High Volume

Structural Composite

Manufacturing

EELCEE is pioneering high-volume structural composite manufacturing. With two decades of R&D experience at the forefront of high-volume composite manufacturing technologies, we are not only leading in manufacturing of fiber reinforced composites for the automotive industry, but also in digitally connected robotic cells and enabled industrial processes, equipment and systems. EELCEE also provides our clients with cost-effective composite design and manufacturing process solutions for rapid industrialization. EELCEE focuses to deliver the solutions with high production rates at an affordable price.

We are a turn-key provider for all aspects of smart preform engineering from material, process, and equipment to digital manufacturing. EELCEE combines automation & equipment with extensive application engineering expertise based upon the renowned R&D competence of some of the world's leading Universities and Composite laboratories at EPFL Switzerland & Purdue University USA. As experts in composite production robotic cells & mass-production automation, we develop custom-designed solutions to meet the specific needs of our customers.

EELCEE is a new company with a long history.

The founders of EELCEE represents a unique life-long combination of hands-on industrial experience and world-renowned research in polymer and composite technology.

As a thermoplastic composite process equipment supplier, EELCEE creates the machinery and manufacturing processes which utilize existing manufacturing infrastructure to deliver parts with continuous fiber reinforcement adaptable for high-volume applications.

SMART MANUFACTURING

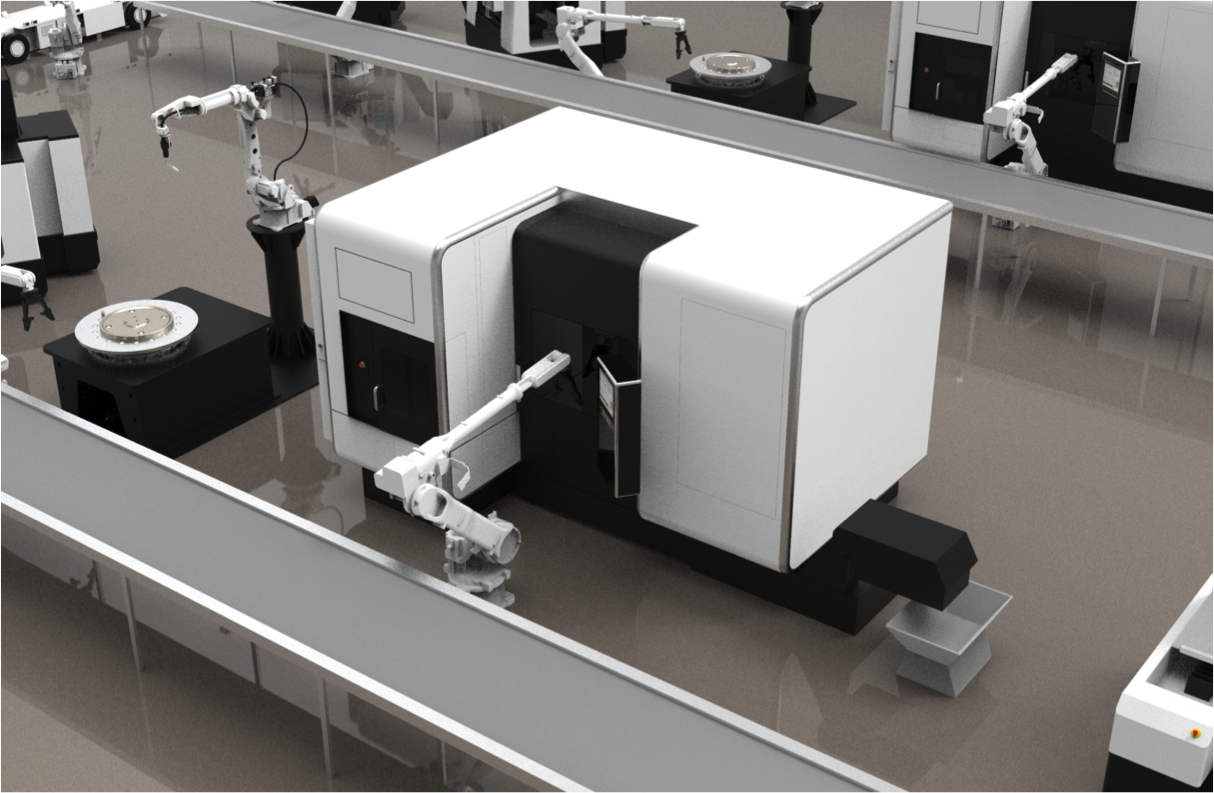

Our smart manufacturing solution combines IIoT technology to collect manufacturing and quality related data on the production floor including the QEE-TECH CELL and other machinery and manufacturing processes. With proprietary optimization software algorithms, we can improve visibility and control, raise production alerts, and make actionable, optimized production decisions and recommendations in real time. QEE-CONTROL tracks raw material, tools, assemblies and finished-products.

EELCEE offers innovation support, application engineering and simulation, prototype manufacturing, preform production, robotic equipment development, and composite process equipment design and manufacture.

EELCEE’s business is targeting applications where both cost and weight reduction are required. A key market for our solutions is the automotive industry, where environmental regulations and customer preferences are requiring simultaneous cost and weight savings. Selectively reinforced polymer composites via smart preforming present an attractive solution, and EELCEE is the industry leader in providing the equipment and expertise necessary to cost effectively design and manufacture with this technology.

EELCEE combines automation equipment development and application engineering expertise to create cost-effective composite structure designs and manufacturing cells. We couple our expertise to the R&D competence of some of the world's leading Universities and Composite laboratories at EPFL Switzerland & Purdue University USA, to develop the future of high-rate composites manufacturing. EELCEE can produce a large number of products efficiently.

We lead research efforts in the areas of composite material manufacture, automation, composite process development, application design including CAD/CAE, integrated sensing, and process simulation in Switzerland, Sweden and South Korea. Solutions are supported by CAD design and predictive engineering capabilities using advanced material and structural modeling.